E type reactive dyes

This series are wool reactive dyestuffs with high performance. It contains double reactive groups, with its water fastness , high stability, good performance in wet fastness and free of heavy metals, can meet OeKo-Tex100 environmental demands.

Main features

E Reactive dyes is a kind of economical wool reactive dyes, especially for wool & cellulose fibre dyeing process .

* Simpl Dyeing process is & easy to operate

* Especially suitable for the dark stain with High absorption rate and fixation rate

* Excellent color fastness properties

* Highly competitive price

| Color Sample | Product | C.I.No. |

|

Reactive Yellow E-R 100% | |

|

Reactive Red E-GL 100% | |

|

Reactive Red E-B 100% | |

|

Reactive Blue E-R 100% | |

|

Reactive Blue E-G 100% | |

|

Reactive Brown E-RN 100% | |

|

Reactive Brown E-BR 100% | |

|

Reactive Navy Blue E-D 100% | |

|

Reactive Black E-B 100% | |

|

Reactive Black E-RH 100% |

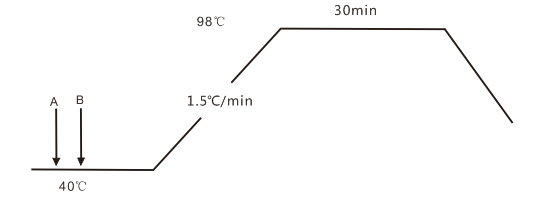

Technology of dyeing

(For example of Wool, only for reference)

Dye dissolved: Dyes beat with cold water, Stir in not more than 60 ℃ warm water to dyes completely dissolved, then Cooling & filter, join to the dyes vat.

Process of graphs

Dyeing prescription

A: Penetrant CA 0.5-1 g/l

Dye leveller B 1-2 g/l

Acetic acid x g/l

Adjust pH=4.5-7

B:Dyes X%

Washing crafts

Put the sodium carbonate or ammonium hydroxide to the dye bath, adjust the PH to 8-8.5, and keep 15-20mintues under the temperature of 80-85℃. Then fully washed it by cold water and adjust the dye bath to PH=5 by the acetic acid.